NEWS

4 Tips for Understanding the Piston Ring Technology

Source: pinterest.com

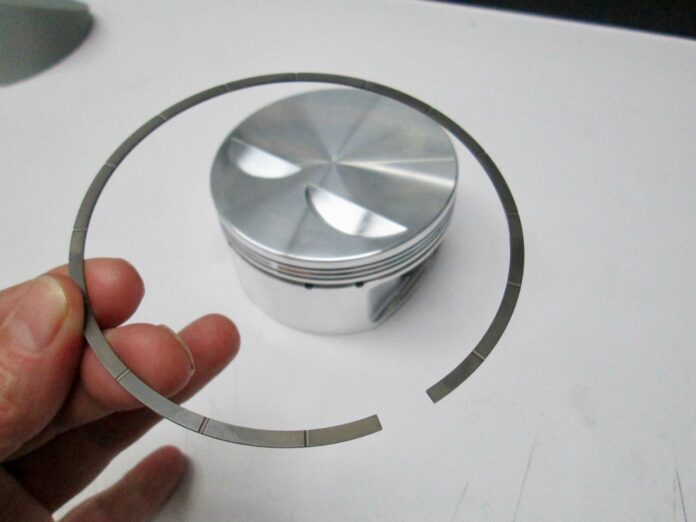

The engine cannot be long-lasting without a ring gap. It is a key part and is often mentioned as a technical issue. However, there are some common ring-gapping mistakes.

That is why you need to find out as much as possible about this topic so that you do not make them. In that case, find out some details that will affect the life and power of the engine.

1. Proper spacing between rings

Source: pinterest.com

To begin with, you need to make the correct distance between the rings so that the engine can function well. For example, the upper compression toe has several main goals. This refers to retaining compression, transferring heat from the piston to the cylinder, etc. That is why the most heat is retained there. It is important to take this into account, as this will reduce the risk. It is necessary to make as little space as possible so as not to put too much pressure in the chamber. The ring ends should be completely parallel to each other during installation.

2. Potential hazards

Source: pinterest.com

Of course, you must always have potential problems in mind. They exist in every industry, especially when it comes to parts like these. One of the bad things that can happen to you is that the upper ring is too small. For example, when the ends expand, they will simply come into contact with each other.

However, a terrible malfunction can happen to you during the expansion and contraction of the upper ring. It thus functions at a certain temperature. The higher the temperature, the more the cylinder increases. In this way, much more heat is introduced, and the ring continues to expand. Then there is a failure which is a consequence of a continuous cycle of high heat and high external pressure.

We're sure you don't want this to happen to you, so pay attention to it.

3. Follow the instructions

Source: pinterest.com

To avoid problems and do everything right, the most important thing is to read the instructions. That is the only correct way to use it. Don’t ignore the important information that is there, but also check online. This applies to various forums and similar sources that contain a lot of recommendations that will be useful to you. On the Youtube platform, you will be able to see videos that will also be useful to you. However, the process is not complicated. You need to insert the ring into the wrinkles, and for that purpose use the squaring tool to align it properly.

4. Be careful during the process

Source: pinterest.com

In addition to the above, there are a few other mistakes that are easy to make if you do not pay enough attention to certain things. For example, filling rings initially measuring and gaps. While some draw conclusions in advance when it comes to ring size, you always measure first.

Count your turns, because that way you will know how much material has been removed. If you are not aware of this, you will have to buy another ring due to a mistake. You also need to make sure that the ring and gaps are in the correct position. Do not rush, because this process requires you to take the time. Only then will you be precise. Work little by little and keep checking things out.

Conclusion

Save money and time by learning more about how piston ring technology works. Don’t forget to pay attention to details, because that’s the only way to avoid mistakes that can cost you dearly.